The story of British porcelain starts over 3,000 years ago in China. By around AD100 the Chinese were making hard, high-fired pottery containing kaolin clay and petuntse rock, a material we now call stoneware. They kept improving it for many more years until one day, in about AD800, they achieved the perfect translucency that we associate with porcelain. Soon they had built huge ‘dragon ovens’ that could fire up to 23,000 pieces at a time.

The city of Jingdezhen in southern China became, and still is, the centre of this colossal industry, bellowing out fire and smoke and creating towering mounds of pottery waste. A lively trade emerged, first to the Islamic world, then onwards to Europe. Marco Polo brought a small, beautifully textured jar back to Venice in 1295. Because of the wonderfully smooth, translucent surface of this material, the Venetians called it porcellini, or little pigs, which was also their word for cowrie shells. And so, porcelain became a thing in Europe.

You might also like our favourite blue and white ceramics

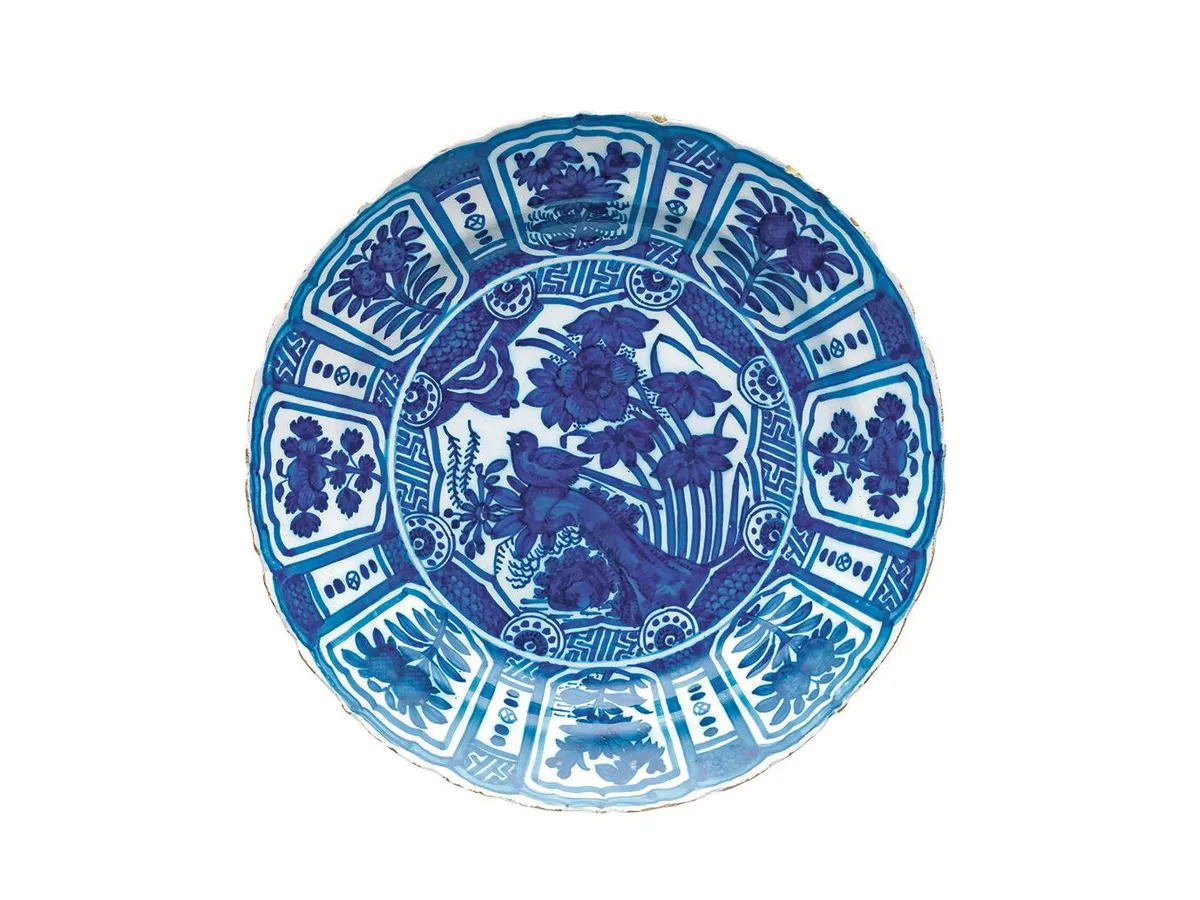

Small consignments of these coveted blue and white pieces would find their way along the Silk Route to Europe. Then, in 1507, the Portuguese started the organised trade of porcelain in ships called carracks – hence the name kraak ware, which is applied to this early Chinese export porcelain. In 1602, the Dutch ransacked some of these vessels, selling off the contents to all the nobility of Europe. This strategic move created a huge demand and prompted the Dutch VOC to establish its own trade links with China. The English East India Company followed suit a bit later.

Blue and white wares became all the rage in Europe. Look closely at the still lifes of the Dutch 17th-century masters and you will see beautiful blue and white kraak bowls, plates, chargers and jugs. Once Europeans had seen real porcelain, they couldn’t get enough of it! But the Chinese recipe for porcelain was a closely guarded state secret. So what do we do if we can’t have something? We imitate! And so, a beautiful, tin-glazed soft earthenware, now called Delftware, was developed to satisfy demand: it was cheap and looked just like the kraak ware that was so fashionable.

However, the Europeans’ desire to make their own real porcelain sparked a mad dash to secure the recipe. Competition was so fierce that Europeans threw alchemy at their attempts to create this ‘white gold’. And this is where the story becomes really bizarre. Augustus the Strong, King of Poland, kept a young alchemist called Johann Friedrich Böttger in protective custody – basically locked in a dungeon in Meissen, near Dresden – to make gold.

You might also like how to decorate with blue and white china

In 1704, when Böttger’s experiments had produced no results, the frustrated Augustus employed a famous scientist, Graf von Tschirnhaus, to work with him. But Von Tschirnhaus had very different plans: he was not looking for mere gold; he was looking for white gold.

Finally, in 1708, after four years of hair-raisingly dangerous and noxious experiments (which Edmund de Waal brilliantly describes in his book, The White Road) Von Tschirnhaus and Böttger created their first piece of porcelain, using a combination of alabaster and locally mined kaolin. This was the beginning of European porcelain. Soon the Meissen factory was established and it is still in operation today.

But this is not the only crazy part of the story. While the alchemists were busy in Meissen, a French Jesuit father, Père d’Entrecolles, was moonlighting as a spy in the porcelain factories of Jingdezhen. In 1712, a detailed account of Chinese porcelain production was published in a book. A Jesuit father, welcomed to China as a man of religion and integrity, divulging the country’s most closely guarded secret is pure James Bond! Yet he certainly helped speed things up, and France started making soft-paste porcelain at St Cloud.

This contained vitreous material which resulted in a beautiful, perfect body – although not as strong as the Chinese and Meissen hard-paste porcelain. St Cloud gave way to Vincennes, which became Sèvres, also still in operation today. Meanwhile, in Britain, the East India Company was importing huge quantities of porcelain direct from China.

You might also like how to create displays with blue and white china

Ships were loaded with it not only because porcelain was so popular, but also because it provided useful ballast to safely guide these vulnerable ships through their perilous journey around the wild waters of Africa. The porcelain was then sold off to retailers at auctions in London.

However, by 1740, the knowledge gained in Europe by itinerant migrants was making its presence felt, and all over the country people started to experiment with making their own porcelain. And as the British Isles have a unique geological make-up of rock, stone and clay deposits, people had plenty of materials with which to experiment.

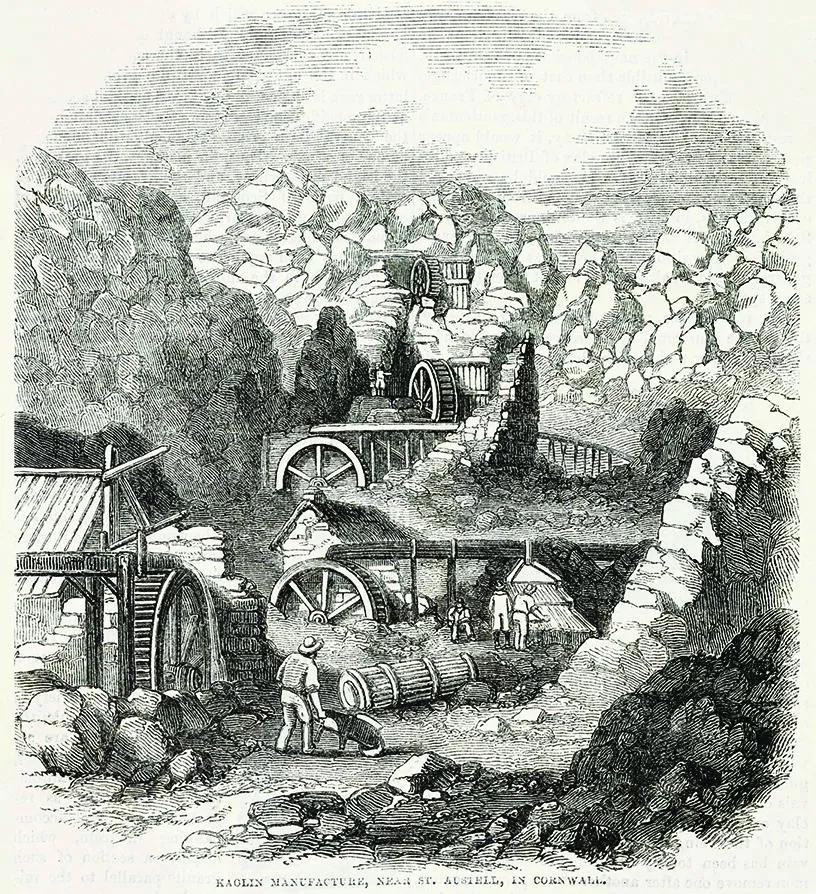

Some used kaolin clay, similar to what had been used in China, others used feldspar rock, lime or soapstone. Most of it came from Cornwall – and if you are one of the many people who turn pots as a hobby today, this is probably where your clay comes from.

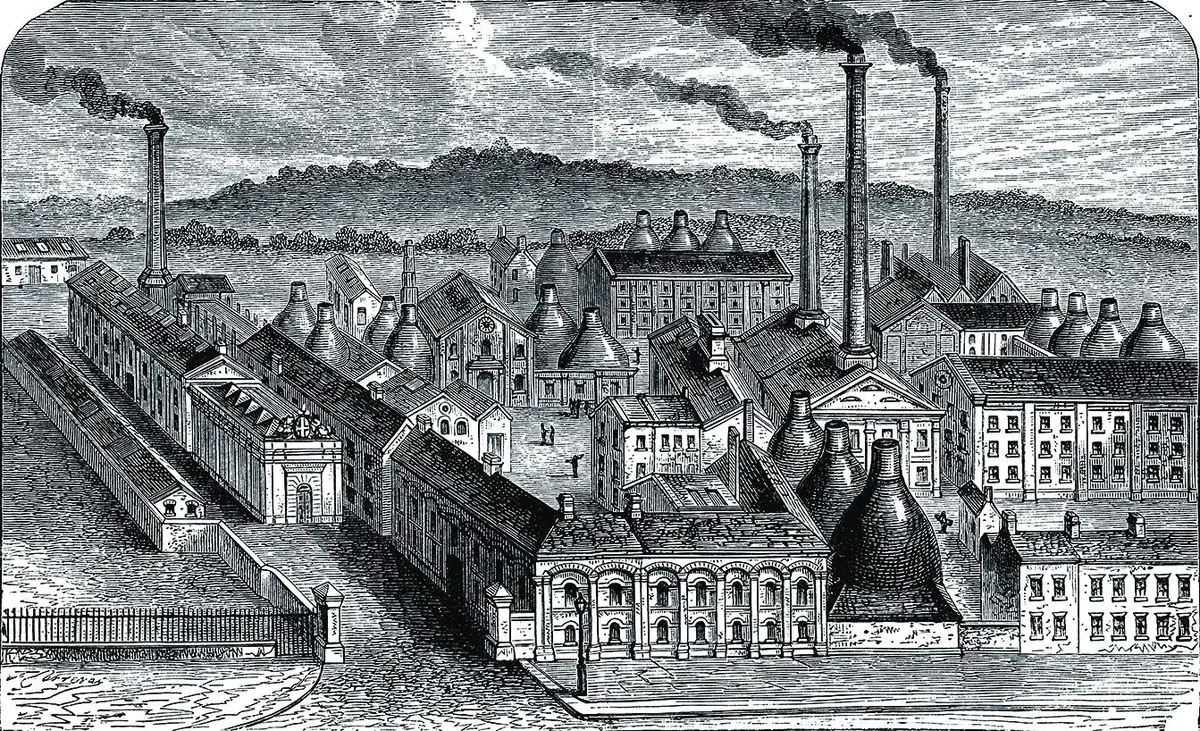

So if you imagine arriving in Britain in around 1740, clambering up the white cliffs of Dover and peering across the island in front of you, you will see that over a period of about 10 or 20 years, small porcelain ‘manufacturies’ are springing up all over the land. If you let your eyes wander you will notice that dotted around London are Limehouse, Bow, Vauxhall and Chelsea. Further to the north sits Derby, nestled in the heart of England.

Moving further north you come upon Newcastle-under-Lyme and Longton Hall in Staffordshire, with Liverpool just to the west. Moving south you find Worcester, then Bristol where England meets Wales.

Directly south from there on the Devon coast is Plymouth and finally, if you let your eyes move west to the far corners of Cornwall, you see clay being dug from huge pits, one of which houses today’s Eden Project. If we view all these enterprises equally, it is fascinating to see how many people are tinkering with porcelain kilns, all within this very short period.

Today, we tend to only remember a few of them for the simple reason that most came and went within a few years, leaving behind very few traces. Making porcelain is prohibitively expensive, particularly if you lack experience and suffer a high proportion of kiln failure that must be discarded.

Porcelain production in Britain has always been privately funded, so factories would come and go depending on the business acumen of their managers and the depth of the pockets of their financial backers. Some of these small short-lived potteries did important pioneering work, although they are now lost to history.

Only four early factories made it through a significant period of time and are therefore still well-known today: Chelsea, Bow, Derby and Worcester. Of these new English porcelain factories, many had grown out of the countless existing potworks where excellent earthenware was made, but several were started by enterprising immigrants.

In Chelsea, a Walloon Huguenot silversmith called Nicholas Sprimont applied knowledge picked up in France to turn his silver dishes into porcelain. In Bow, Irish immigrant Thomas Frye conducted experiments in his friend’s backyard using ‘Cherokee clay’ imported all the way from America.

Meanwhile, a French Huguenot refugee called André Planché was firing porcelain toy animals in his backyard in Derby, based on skills his father had learned at Meissen. And in Worcester, it was Dr John Wall, an Englishman, physician, artist and philanthropist, who tinkered with porcelain in the kitchen of his friend’s apothecary shop. But more on all of this at a later date!

Skills brought from Europe by itinerant migrants enriched the 18th-century spirit of experimentation. And once this met the British hunger for porcelain and their expertise in building a cracking good kiln, suddenly the time was ripe for the beginning of a rich and wonderful new chapter in the British decorative arts that collectors all over the world still enjoy today.